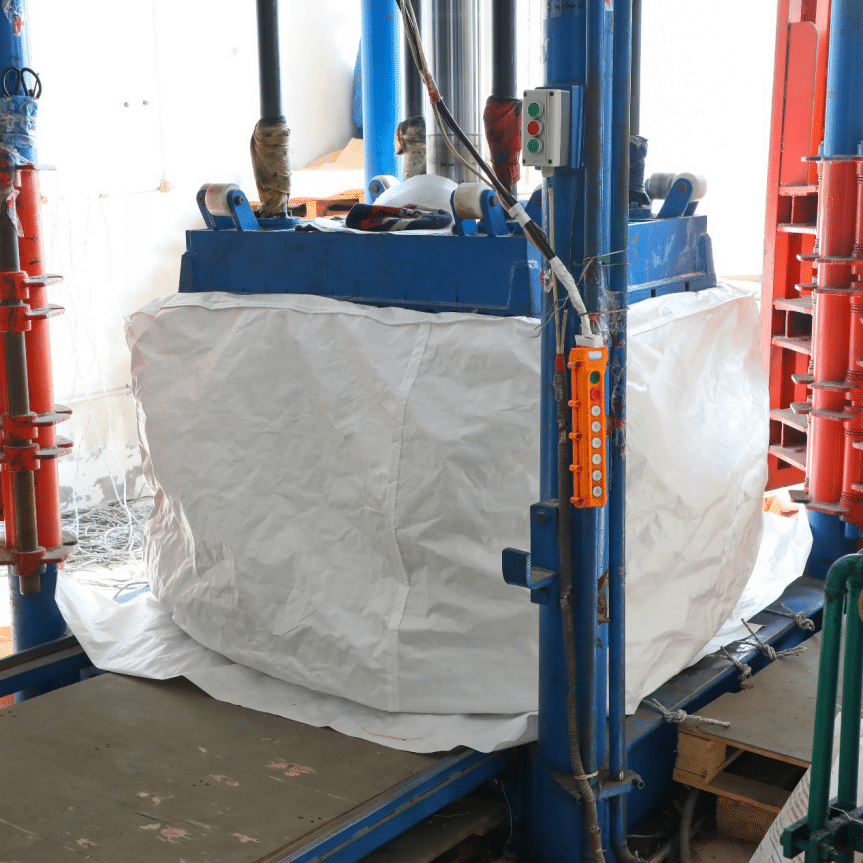

With the development of recent years, China has become a production base of container bags. However, more than 80% of the bags produced in China are exported, and the requirements of foreign markets for the bags are also increasing. With the continuous expansion of storage function and scale and the wide use of the bags in bulk packaging, how to control and prevent the electrostatic damage caused by the packaging goods of the container bags has attracted the attention of Europe and America and other countries. In order to strictly control the quality, strive for a larger foreign market, ensure the safety of the goods transportation, it is very important to know the harm and prevention knowledge of static electricity generated by the packing goods in the storage. The harm of static electricity has been paid much attention in the production of packaging industry, but in the storage and transportation of packaging goods, the harm and prevention to static electricity is still a weak link.

There are two main reasons for static electricity in the storage of packaging goods

The first is internal reason, namely the conductivity of the material; the other is the external reason, namely the friction, rolling and impact between the materials. Many goods have the internal factors of static electricity, and they can not be separated from handling, stacking, covering and other operations in storage. Therefore, friction, rolling and impact between the packaging materials will inevitably occur. In the process of stacking, the plastic packaging of general commodities is easy to generate static electricity due to friction.

The electrostatic hazard in the storage of packaging goods is very easy to generate electrostatic sparks when the electrostatic potential is high on the surface of the packaging. The harm is mainly manifested in two aspects: one is to cause the explosion accident. For example, the contents of the package are inflammable substances. When the steam they emit reaches a certain proportion to the air, or when the solid dust reaches a certain concentration (i.e. the explosion limit), it will explode once encountering electrostatic sparks. Second, electric shock is produced. If electrostatic discharge is produced during the handling process, it will bring the operator the discomfort of electric shock, which occurs frequently when the plastic packaging goods are transported in the warehouse. During the process of handling and stacking, electrostatic high potential discharge is produced due to strong friction, even the operator is knocked down by electrostatic discharge.

Prevention of electrostatic hazards of packaging materials in storage: the following methods are generally used to prevent and control the electrostatic hazards in the storage of packaging goods:

1. the packaging shall be controlled to avoid static electricity as far as possible. For example, when handling flammable liquid, it is necessary to limit its violent shaking in the packaging barrel, control its loading and unloading mode, prevent the leakage and mixing of different oil products and prevent water and air intake in the steel drum.

2. take measures to make the generated static electricity escape as soon as possible to avoid accumulation. For example, good grounding devices are installed on tools such as handling, increasing the relative humidity of the workplace, laying conductive floor on the ground, spraying conductive coating on some tools, etc.

3. add a certain amount of anti charge to the charged body to avoid the rise of static voltage (such as induction static neutralizer).

4. in some cases, electrostatic accumulation is inevitable, and the electrostatic pressure rises rapidly and even generates electrostatic sparks. At this time, measures should be taken to make it discharge but not produce explosion accident. For example, inert gas is filled in the storage space of flammable liquid, alarm device is added, and exhaust device is adopted to make flammable gas or dust in air reach explosion limit.

5. in places with fire and explosion hazards, such as storage and distribution of chemical dangerous goods, staff wear conductive shoes and electrostatic work clothes, etc., and timely eliminate static electricity brought by human body.

Post time: May-10-2021